From Obsolescence to Overdrive: The U.S. Industrial Transformation During WWII

How America Revamped Its Manufacturing Might to Become the Arsenal of Democracy

It’s June and that means two things.

First, it means that 2024 is screaming by. Second, it means that there are only 3 weeks until Reindustrialize 2024.

In honor of that and to help everyone prepare for the conference, I’m planning to focus on the industrial base this month.

This week, we’re going to roll back time to World War II.

Interbellum

Following the First World War, pacifism grew across Europe and the United States.

Hoping to avoid a repeat of that war, US Secretary of State Frank Kellogg and French Foreign Minister Aristide Briand negotiated the Kellogg-Briand Pact. The pact essentially outlawed war as a means of resolving international disputes (as an aside, the Pact remains in effect today).

The Senate lashed out at the industrial base, calling them “Merchants of Death” and accusing them of intentionally dragging the United States into the war for profits. Average Americans reading the news grew increasingly distrustful of the Defense Industrial Base companies. Combined with the Great Depression, this distrust led to a desire for isolationism.

Congress embraced that sense of isolationism and passed a series of Neutrality Acts throughout the 1930s.

The backlash also changed how the military contracted for goods and services with industry. During World War I, the government made heavy use of Cost-Plus-a-Percentage-of-Cost (CPPC) in contracting. This incentivized industry to increase their costs, as their profits would increase proportionally. This model was quickly abandoned in favor of Cost-Plus-a-Fixed-Fee (CPFF) which would pay a fixed profit rather than one proportionate to the cost incurred by the contractor.

Congress also stepped in, in 1934, passing the Vinson-Trammel Act, which further limited profits for certain military contracts. It also passed the Air Mail Act, which forced aviation holding companies to dissolve hurting the industry further.

To put it quite plainly, the defense industrial base and defense contractors were vilified between the wars leading to its hollowing out.

Rapid Mobilization

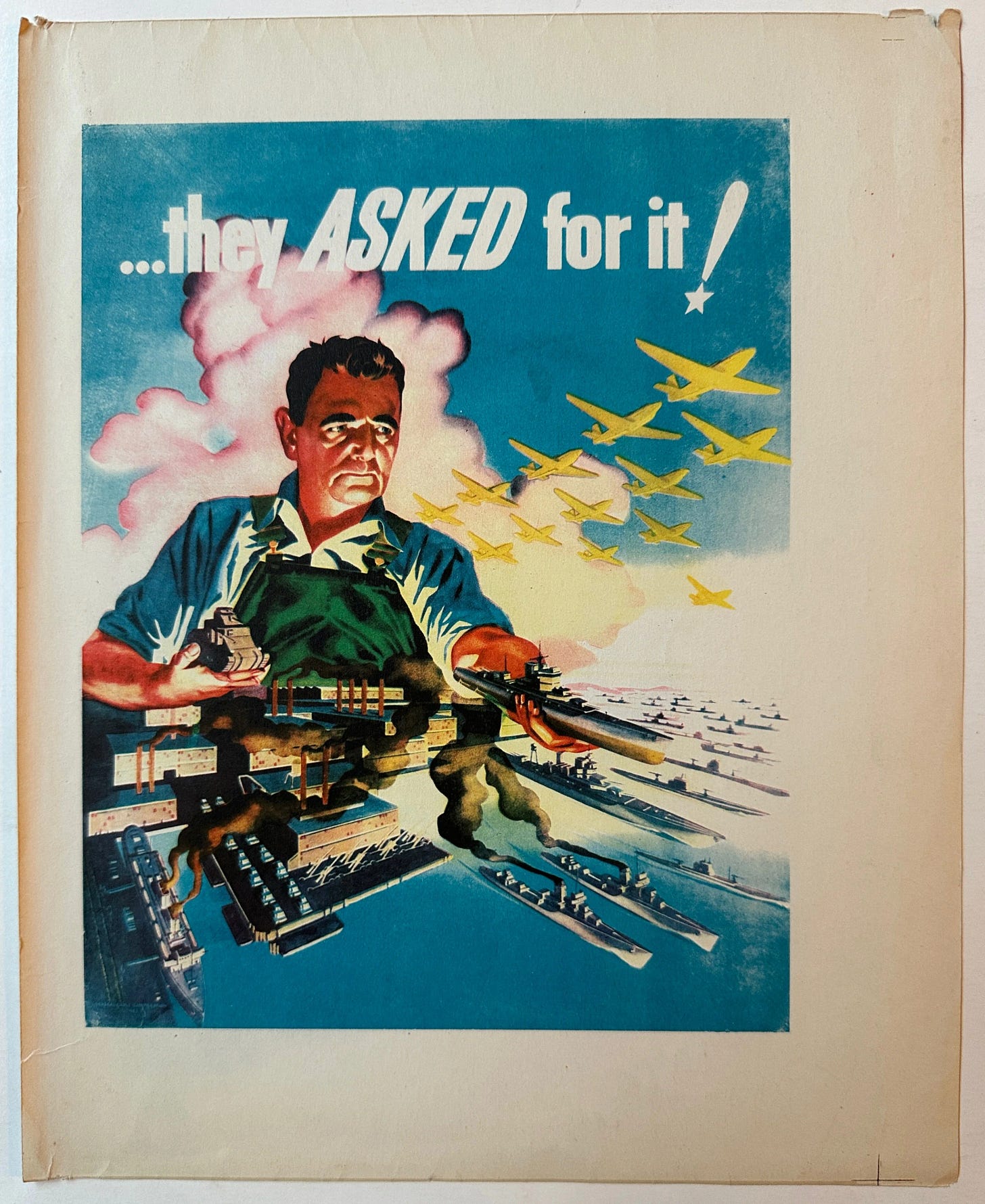

The rise of Nazi Germany and the clear threat it posed to Europe, prompted President Franklin D. Roosevelt to initiate several pivotal policies to transition the U.S. from this weakened state to becoming the most productive manufacturing powerhouse by the end of World War II.

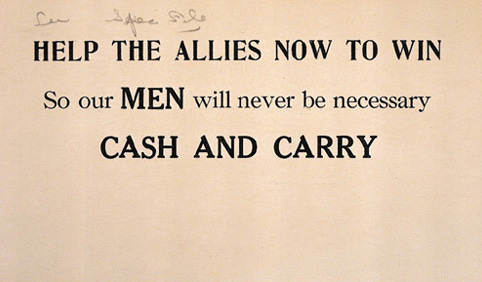

This transformation began with the Cash-and-Carry policy announced in 1939, allowing belligerent nations to purchase arms and supplies from the U.S. as long as they paid in cash and transported the goods themselves. This policy marked the beginning of the industrial ramp-up, providing the US economy with much-needed capital and laying the groundwork for subsequent massive production efforts. For example, Great Britain purchased about $3 billion from the United States under cash-and-carry between 1939 and 1941. Adjusting for inflation, that’s roughly about $50 billion today—and important injection of cash.

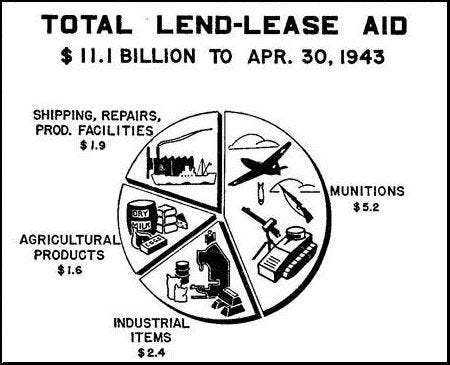

The Cash-and-Carry policy was soon followed by the Lend-Lease Act of 1941, which further accelerated industrial mobilization. Under Lend-Lease, the US supplied its allies, particularly Britain and the Soviet Union, with military and other essential supplies without immediate payment. This act not only strengthened the allies’ ability to resist Axis aggression but also stimulated American industrial production on an unprecedented scale. Factories that had been idle or underutilized due to the Great Depression were reactivated and expanded, leading to job creation and technological advancements that enhanced production capabilities.

Managing and coordinating this industrialization required not just industry to react, but also the government. To meet the needs, the government created several agencies, boards, and offices to facilitate mobilization.

National Defense Advisory Commission (NDAC): Created in 1940 to advise on defense production and procurement.

Office of Production Management (OPM): Established in 1941 to succeed the NDAC, the OPM oversaw all aspects of industrial production necessary for the war effort, prioritizing the production of critical materials and ensuring efficient resource allocation.

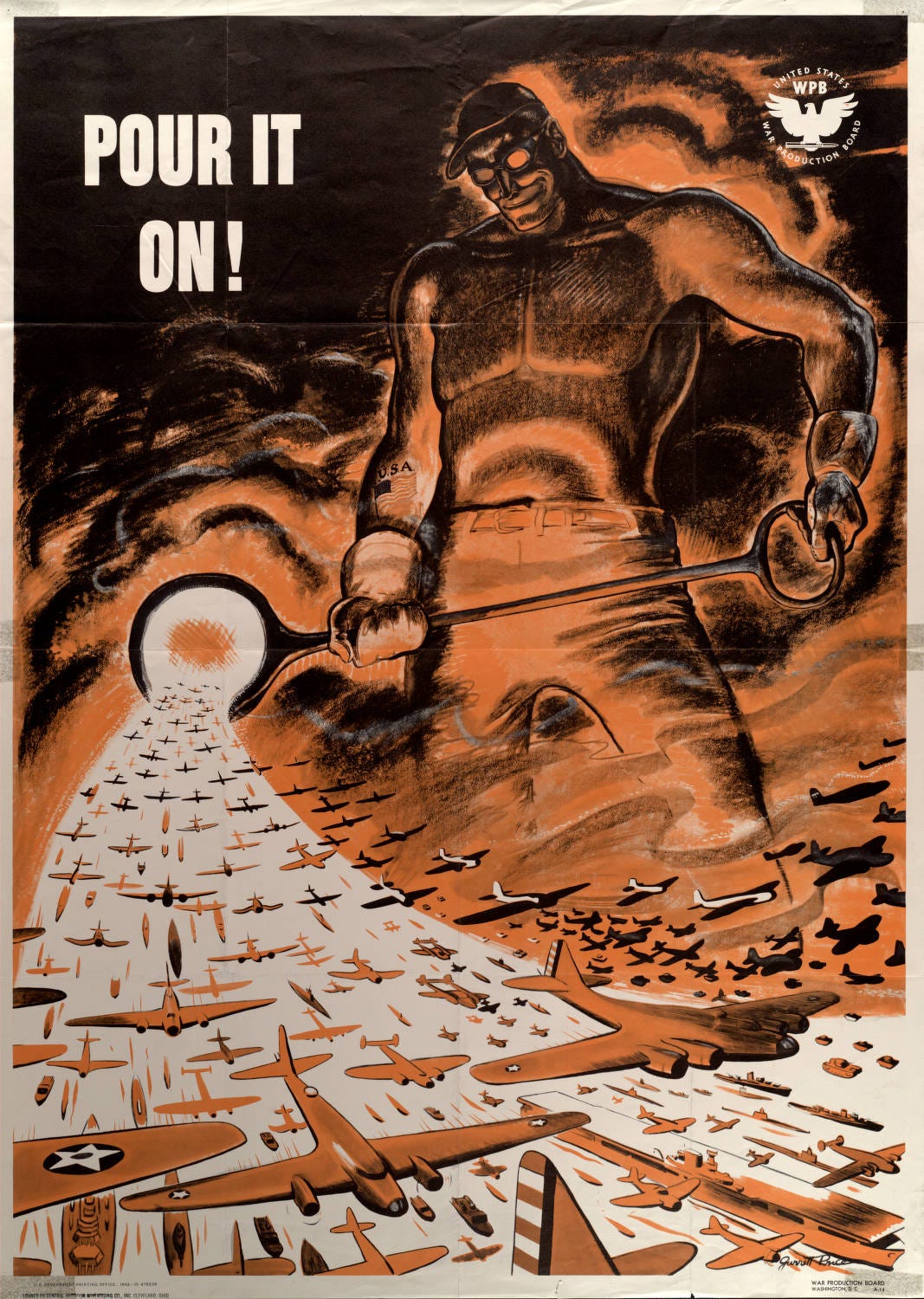

War Production Board (WPB): Established in 1942, the WPB further centralized control over war production, implemented policies to convert civilian manufacturing facilities to military production, standardized parts, and eliminated supply chain bottlenecks.

The transformation of the US industrial base also involved significant changes to procurement and acquisition policies and regulations.

Cost-Plus Contracts (CPFF): Guaranteed manufacturers the cost of production plus a fixed profit margin, incentivizing companies to maximize production without financial loss concerns.

Streamlined Procurement Processes: Reduced bureaucratic delays and heavy investments in new factory construction and equipment, ensuring rapid and efficient production scaling to meet war demands.

Technological innovations and production techniques further contributed to the success of the U.S. manufacturing effort.

Mass Manufacturing Principles: Applied to military production, pioneered by industries such as the automotive sector.

Standardization and Commonality of Parts: Allowed rapid assembly and maintenance of military equipment.

Assembly Line Practices: Refined and scaled up, enabling the production of vast quantities of aircraft, tanks, ships, and other essential war materials.

Expanded Workforce: Included women and minorities, exemplified by the “Rosie the Riveter” campaign, which played a crucial role in meeting production demands.

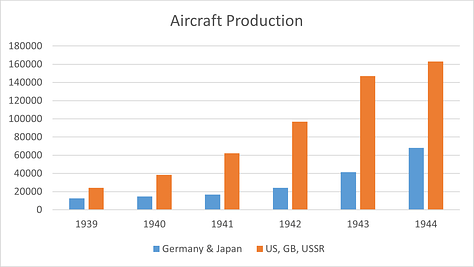

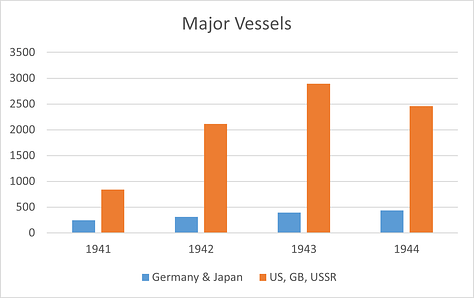

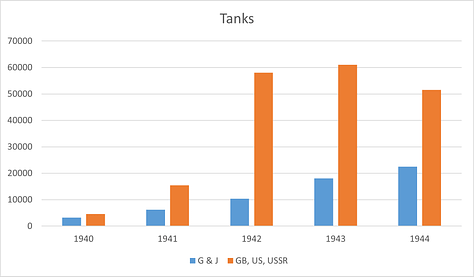

This combination of strategic government policies, investment in infrastructure, and innovative production techniques transformed the U.S. industrial base from a state of near obsolescence in the 1930s to the most productive manufacturing capability in the world by the end of World War II.

Key Factors

To distill this transformation down to the essentials, eight key factors ensured successful mobilization of the industrial base:

Government-Industry Collaboration: Strong alignment and coordination between the government and private industry ensured efficient production of war materials. This obviously requires alignment of incentives.

Mass Production Techniques: The adoption and refinement of mass production techniques allowed for rapid scaling of output. This included the use of assembly lines and standardization of parts, which increased efficiency and output.

Investment in Infrastructure: Significant investments were made in expanding and modernizing factories. This included building new plants and upgrading existing facilities to handle increased production demands.

Skilled Workforce Development: There was a concerted effort to train and employ a skilled workforce, including programs to retrain workers from other industries and the inclusion of women and minorities in the labor force.

Technological Innovation: Continuous innovation and the rapid development and deployment of new technologies played a crucial role. This included advances in manufacturing processes, materials science, and logistics.

Resource Management: Efficient management of resources, including raw materials, energy, and human resources, ensured that production could meet the high demands of the war effort.

Supply Chain Coordination: Effective coordination of supply chains ensured that materials and components were delivered where and when they were needed, minimizing bottlenecks and delays.

Flexibility and Adaptability: Industries demonstrated remarkable flexibility, quickly converting peacetime manufacturing operations to wartime production. This adaptability was critical to meeting the dynamic needs of the war effort.

Now we must ask ourselves, how do we ensure these eight items are included in our Defense Industrial Base, enabled by modern technology? What are the opportunities to supercharge our mobilization and ensure speed in innovation, training, design, and manufacturing?

I look forward hopefully to meeting many of you at the Reindustrialize 2024 event.

Keep building,

Andrew

Just read yesterday's article by Walter Russell Mead in WSJ "AI and the Art of War in Ukraine". It bolsters what you saying and you have likely have read but if not, you would appreciate.